Our riding team joint a product carrier 41.000 Dwd at Brazil and complete rewinding of 1000Kw 440V Generator within 21days

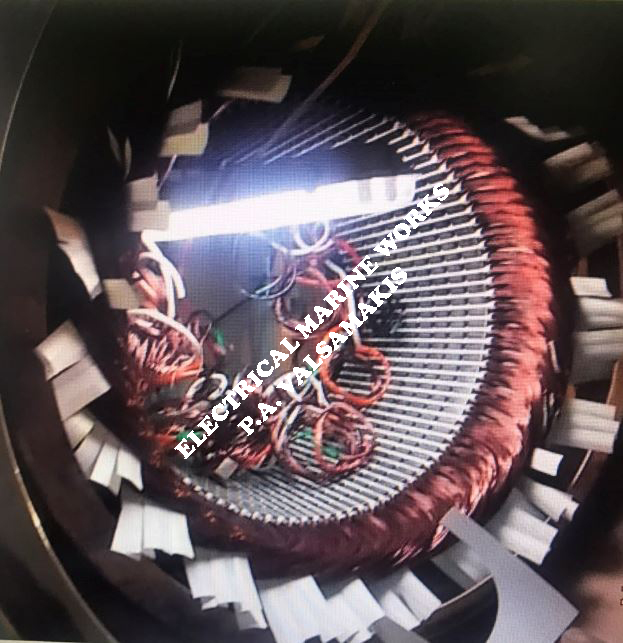

The team then proceeded to inspect the generator with a borescope. During the inspection, the stator core was also checked for short circuits. The stator core turned out the be in good condition so the rewinding could proceed.

For projects like these, a highly detailed preparation is crucial. Not a single item can be forgotten as missing tools and equipment are disastrous for the completion of the job.

Motor disconnection and dismantling

Fault assessment and cleaning of all parts

Tolerance checking of all housings, journals, shafts and spickots

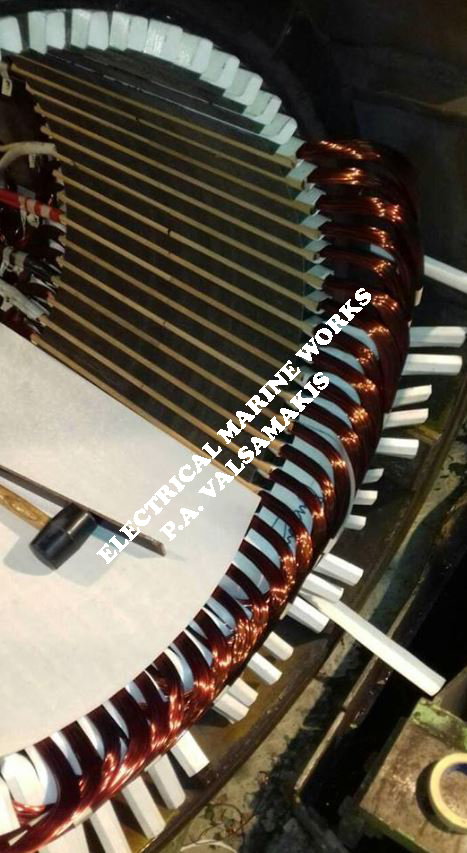

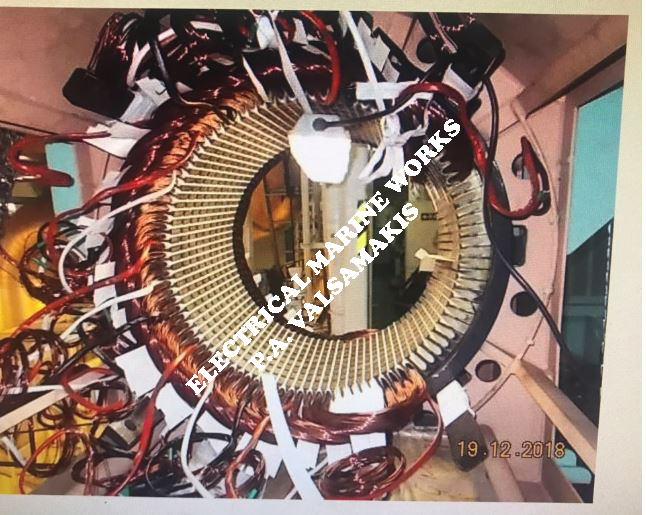

Total rewind undertaken if stator windings are found to be faulty

Stripping, new coil installation and rewind on an armature failing from testing

Commutator earth testing

All parts varnised and baked

Full post-assembly operations and load test

Result for the customer: “a piece of art”

Thanks to the in-situ rewinding aboard the ship, a repair in the dry dock could be avoided and the ship could return to service in a shorter time.

The successful result of this intervention allows ELECTRICAL MARINE WORKS P.A. VALSAMAKIS to show its expertise and eagerness to step out of its comfort zone. The customer called the result ‘’a piece of art’’.

Joomla Plugins